Garage timbers

Timber Specification

All timbers (except glulam) are supplied with a sawn finish. If you order the timber fascia and barge board kit, these will generally be smooth planed to exposed side and edge.

All Post, Beam, Bracing & Cladding timbers are supplied unpainted and undecorated, ready for you to use whatever finish you require. If you are having a larch model it is possible to be left untreated, but spruce models require treatment for resistance to water & UV (Sadolin for example).

All softwood framing and roofing timbers are pressure treated

Garage and Carport Baseworks

Timber frame garages and carports require a sound, level foundation that is set on solid ground, most people choosing to lay a concrete slab, usually at least 150mm (6”) thick and with some steel reinforcing mesh, as this also provides a good floor surface within the confines of the building as well. It may require structural calculations to comply with the requirements of your local Building Control department.

It is usually desirable to have the floor sloping forwards slightly toward the garage entrance doors so that any water that drips off vehicles can drain away.

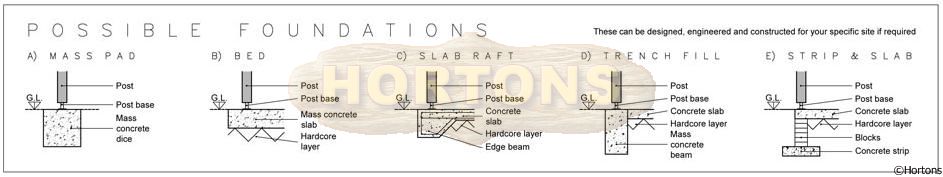

Where a full concrete slab is NOT required, ie. if a gravel drive continues under a carport, then post base pads may be acceptable, providing these are set on a solid base. The required foundation type can depend on a number of factors such as soil conditions, frost heave, proximity to surrounding vegetation, landscape contour (slope of site), fresh landfill, clay, sandstone, loamy soil, water table and structural load. You should refer to your local builder for full advice on a suitable foundation type.

Post and Beam Adjustable Post Bases

If the concrete slab or other floor slopes slightly, or if the foundations are out of level, this could cause a problem with the structure if built onto directly as all posts are the same length. If they are not levelled, then there could be difficulty in constructing the building.

It is also desirable to ensure that the bottoms of all timber posts are kept out of any lying water or rising damp within the base. (timber can get wet, but must be allowed to dry out and keep well ventilated so that it does not remain damp longterm). The solution is to use adjustable metal post bases. Each of these is fitted with coach bolts onto the bottom of each post. If there is any difference in the level of the foundations for these, the height of the base can be screwed up or down to suit (max 50mm) so that you can get them all exactly level. At the same time, the sturdy galvanised metal base keeps the bottom of each post raised up out of any water, able to be kept dry, well aired, and damp free.

The very bottom of these post bases is then bolted down to the concrete or other foundation, to be held in position and free from any uplift forces that may occur.

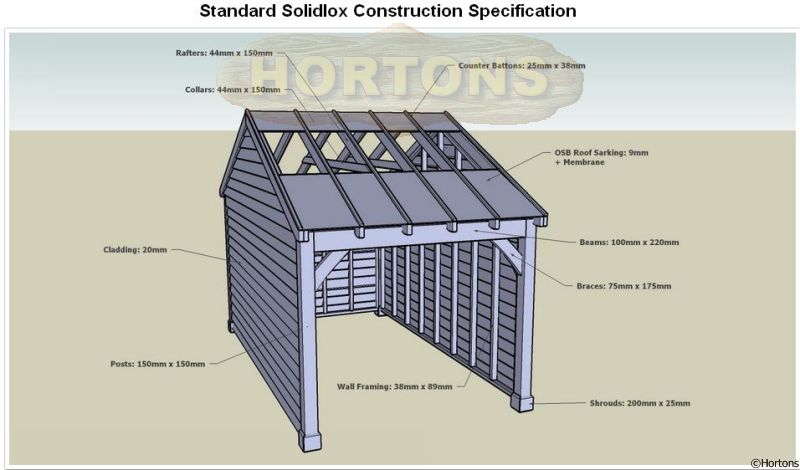

Standard Construction Specification

Room Above Insulation

When opting for insulation in our room in roof Garages or Carports, our specification is intended for incidental and storage use, with no permanently installed heating system (ie non-habitable). This should be made clear on any Building Regulations application for the structure otherwise you may be asked for a higher standard than required (ie. habitable specification). The Local Authority will also require a much higher fee for assessing your application - approx £500 - £600 as opposed to approx £200 for an unheated, non-habitable space. However, we can provide this higher specification if required, but it can add significantly to the cost. Please speak to us if you require a specification that needs to comply with Building Regulations for a habitable space.

Assembling the kit yourself

Although we recommend that we install your Post & Beam structure for you, this system does enable you to DIY install relatively easily with the assistance of a qualified Carpenter or Builder with Timber Frame knowledge.

If you choose to self install, the following should be considered:

It is possible to erect the post and beam structure using only hop ups. Above this you will need scaffold towers.

Above eaves height, the sarking, breather membrane, counter-battens and tiles can be installed using 2 roof crawler ladders.

Fixings

You will need sufficient quantity of the following items for self-assembly:

100mm round head Nails (or gun nails) for nailing wall frames

100mm round head Nails (or gun nails) for nailing roof timbers

50mm sherardized round head Nails for feather edge wall cladding

50mm sherardized round head Nails for fixing OSB sarking to rafters

75mm sherardized round head Nails for fixing counter batten through OSB to rafters

60mm Screws for floor deck (10 per sheet) - If having a room in roof option

Glue for floor deck (1 tube per 8 sheets)) - If having a room in roof option

All of the above should be non-corrosive or stainless steel

Decorating and Maintaining your post and beam garage / carport

When using larch, many people choose not to apply any treatment or finish whatsoever and allow the timber to ‘grey out’ naturally. Others may prefer to add some form of oil, wax, varnish, or paint to match in with other decoration or construction materials.

Spruce should be treated and maintained for resistance to water and UV (Sadolin for example).

Larch and cedar timber cladding can be left to ‘grey out’ naturally, although if less durable timbers are used then some form of paint, or bitumen treatment should be used.

Normal ongoing decoration and maintenance of timber then applies.